Client Profile:

Mid-sized engineering components manufacturer supplying to automotive OEMs (annual turnover: ₹170+ Cr)

Challenges:

- Cash flow always under pressure due to high dependency on working capital loans

- No product-level profitability insights; pricing was assumption-based

- Monthly MIS was delayed and Excel-based, leading to reactive decision-making

- Founders lacked visibility into gross margins and plant-wise financial control

CFO Pulse Approach:

🔰 CFO Shield (Stage 1)

- Conducted a 12-month 100% transaction audit to clean up books

- Ensured accurate and consistent classification of direct vs indirect costs

- Fixed accounting inconsistencies across plants

📊 CFO Dashboard (Stage 2)

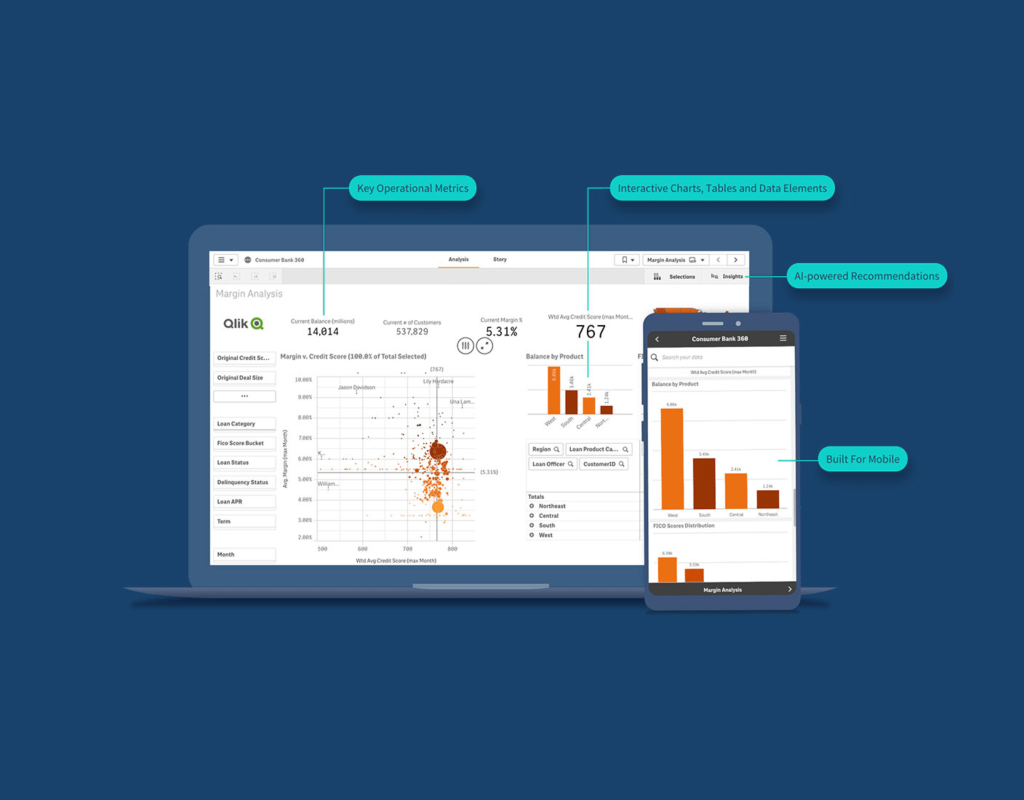

- Built custom Power BI dashboards showing real-time revenue, margins, cost variances

- Developed plant-wise, product-wise, and customer-wise profitability tracking

- Created a daily cash flow dashboard linked to live bank balances & payables

🔍 CFO Lens (Stage 3)

- Monthly performance review meetings with department heads

- Identified electricity cost inefficiencies → cost-saving project reduced power costs by ~8%

- Improved gross margin monitoring → better control over pricing & discount leakages

🧠 CFO Brain (Stage 4)

- Conducted cash conversion cycle (CCC) analysis → reduced CCC by 21 days

- Strategic move: discontinued one low-margin product line, improving overall GP% by 3.2%

- Built 3-year growth forecast model to guide capex planning

Tangible Impact:

- From ₹10 Cr CC/OD limits → moved to cash surplus status with ₹17 Cr in FDs

- Revenue scaled from ~₹39 Cr to ₹170+ Cr within 3 years (with stronger financial discipline)

- Gross margin improved by 4.8% overall

- Created a culture of data-driven financial decisions across all departments